One recurring design choice is between 2-pin and 3-pin connectors. The difference may look trivial—just one extra pin—but in reality, it shapes how safely and efficiently a system operates. That third pin often transforms a basic circuit into a reliable, communication-ready link that improves diagnostics, reduces failures, and ensures compliance with increasingly strict vehicle standards.

Basic Definitions and Structural Differences

As 2-pin connector contains two contacts:

- Power (positive) – supplies current to the load.

- Ground (negative) – returns current safely.

It’s simple, compact, and inexpensive. You’ll find it in circuits that don’t need complex communication, such as halogen headlights, cabin blowers, or resistive heaters.

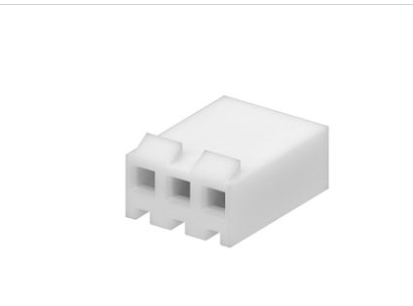

As 3-pin connector adds a third contact:

- Power.

- Ground.

- Signal line – transmits data or control commands.

That third pin makes it possible to gather information, send feedback, and integrate with an ECU.

Just like that:

- 2-pin: A halogen bulb, where one pin powers the filament and the other grounds it.

- 3-pin: A coolant temperature sensor, which needs one pin for power, one for ground, and one to send precise readings to the ECU for real-time engine management.

Performance and Reliability Comparison

- Signal Integrity and Interference Resistance

Cars are noisy electrical environments. Numerous sources, including alternators, ignition systems, and various types of motors, can produce electrical noise or electromagnetic disturbances. With only two pins, a connector has no dedicated signal separation, so readings may drift or become unstable.

A 3-pin connector improves signal clarity. In an oxygen sensor, a 2-pin version only outputs a rough rich/lean signal, while a 3-pin design includes a dedicated signal wire. That cleaner data helps the ECU fine-tune fuel injection, lowering emissions and improving fuel economy.

- Fault Tolerance and Reliability

2-pin connectors provide no redundancy. If a ground fails, the circuit dies. In contrast, 3-pin connectors can separate ground and signal paths, which reduces the likelihood of total failure. This matters in safety-critical systems like ABS, where one bad connection can compromise braking stability.

- Current vs. Signal Handling

2-pin connectors: Best for high-current devices where precision isn’t critical—such as radiator fans or pumps.

3-pin connectors: Better for sensors and actuators that require clean, low-current signals, like throttle position sensors.

Safety and Application Area

In simple lighting or motor circuits, 2-pin connectors are safe enough. But when accurate data is essential—like fuel injection or brake monitoring—the lack of a signal line creates risk.

3-pin connectors not only provide cleaner data but often include weatherproof seals and locking mechanisms. This prevents disconnection in environments full of vibration, moisture, or dirt.

Applications in practice:

- 2-pin: Brake light circuits, fuel pumps, radiator fans.

- 3-pin: Mass air flow sensors, crankshaft position sensors, and electronic throttle bodies.

Installation and Maintenance

From a mechanic’s perspective, installation speed and reliability matter as much as design theory.

- 2-pin connectors: Quick to install, fewer parts, and easy to replace. Perfect for components like bulbs, which often fail and need fast swaps.

- 3-pin connectors: Slightly more complex but much more secure. The built-in locking mechanism keeps the connector securely in place, even under the intense vibrations commonly found in engine compartments.

Replacing an oxygen sensor. With a 3-pin connector, the job is unplug-and-replace—no splicing or soldering. The mechanic saves time, reduces mistakes, and ensures the new sensor communicates correctly with the ECU.

Comparison Tables

Fleet Operations

A taxi fleet using 2-pin connectors for headlights faced constant bulb failures due to corrosion. The short repair time was offset by the sheer frequency of replacements.

In contrast, when the same fleet upgraded its cooling fan sensors to 3-pin sealed connectors, repair downtime dropped by 30%. The sealed design resisted dust and moisture, while the signal pin provided stable feedback to the ECU, preventing false alarms.

Comparison Table:

| Feature | 2-Pin Connector | 3-Pin Connector |

| Functionality | Power + Ground | Power + Ground + Signal |

| Signal quality | Prone to noise, unstable data | Stable, resistant to interference |

| Typical applications | Lighting, fans, fuel pumps | Sensors, ECUs, throttle bodies |

| Safety & reliability | Basic, risk of loose fit | Higher, with seals and locking tabs |

| Cost | Lower upfront | Higher upfront, but better long-term ROI |

The difference between 2-pin and 3-pin connectors isn’t just about pin count—it’s about function, safety, and cost.

- For simpler circuits requiring just positive and negative leads, 2-pin connectors are often sufficient. They’re simple, cheap, and effective for high-current devices like lights and pumps.

- Choose 3-pin connectors for any circuit involving sensors, actuators, or critical data transfer. They ensure reliability, improve diagnostics, and reduce lifetime costs.

As vehicles grow more electronic, the 3-pin connector has become the smarter, more future-ready choice.