Application of cable ties in automotive wiring harnesses

Automotive wiring harnesses are meticulously arranged throughout various sections of the vehicle body. In addition to rubber components, an extensive array of zip ties and various fastening devices are essential to bundle the harness securely and fasten it to the vehicle chassis, while concurrently ensuring waterproofing and vibration dampening functionalities.

Wiring harness zip ties and fasteners find widespread application in a multitude of industries, including electrical installations, wiring harness manufacturing, construction, packaging, and even in extreme environments such as marine applications.

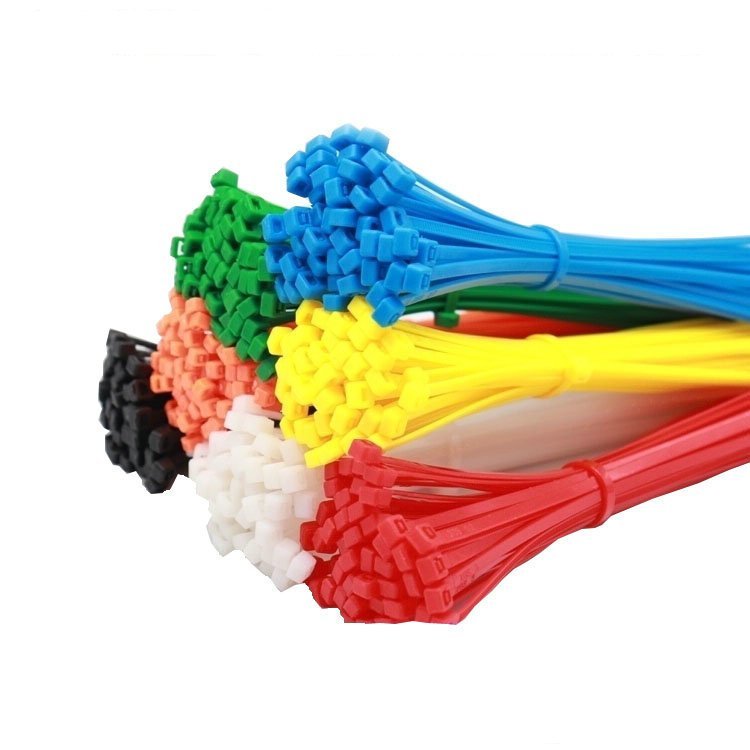

Common cable tie product types

Common types of zip tie products include those with internal teeth, external teeth, releasable ties, non-toothed ties, stainless steel ties, direct-fix ties, integrated fix ties, ties with securing heads, and various types of clips.

Among these, the most frequently employed varieties in automotive wiring harnesses are the structurally complex integrated fix ties, ties with securing heads, and assorted fastening clips.

Materials and Types

The materials used for automotive wiring harness zip ties typically consist of modified and toughened PA66 (polyamide 66), with a lesser proportion utilizing materials such as PP (polypropylene) and polyethylene.

Based on the shape of their anchoring points, zip tie products can be categorized into umbrella-type, cap-type, bolt-type, clamp-type, and plate-type designs. Generally, the most commonly applied types include umbrella-type caps, wedge heads, and fir tree head zip ties.

The assembly holes in the sheet metal of major automotive manufacturers typically present circular or elliptical shapes, with varying sizes.

For instance, Volkswagen predominantly utilizes circular holes with a diameter of 6.5 millimeters, while Japanese automotive brands favor elliptical holes measuring 7.12 millimeters.

conclusion

The use of zip tie products within automotive wiring harnesses is substantial, with a diverse range of products available. Although their structures tend to be relatively simple, there are stringent requirements in terms of raw materials, product dimensions, mold precision, and manufacturing processes, classifying them firmly within the realm of precision injection-molded components.