With the rapid advancement of new energy vehicle technology, electric vehicles (EVs) and hybrid vehicles are becoming the future trend in transportation. In this process, automotive connectors play a crucial role as key components. Here is an overview of the main applications of automotive connectors in new energy vehicles and their characteristics.

Battery System Connections

Applications

- Battery Pack Connections: Connectors are used to link various battery cells within the battery pack, ensuring overall electrical transmission and management of the battery system.

- Charging Interfaces: Connectors facilitate the connection between the battery and charging equipment, enabling efficient and safe charging.

Characteristics

- High Current Capacity: Battery systems handle large currents, so connectors must have sufficient current-carrying capacity.

- Good Insulation Performance: Ensures safe and stable operation of the battery pack during charging and discharging, preventing short circuits and overheating.

Motor Control Systems

Applications

- Motor Connections: Connectors link the electric motor with control modules, transmitting control signals and power to the motor.

- Motor Temperature Control: Connectors link temperature sensors to the control system, monitoring the motor temperature in real time to prevent overheating.

Characteristics

- High Reliability: Motor control systems require highly reliable connectors to ensure proper motor operation.

- Vibration Resistance: Motors generate vibrations during operation, so connectors need good vibration resistance.

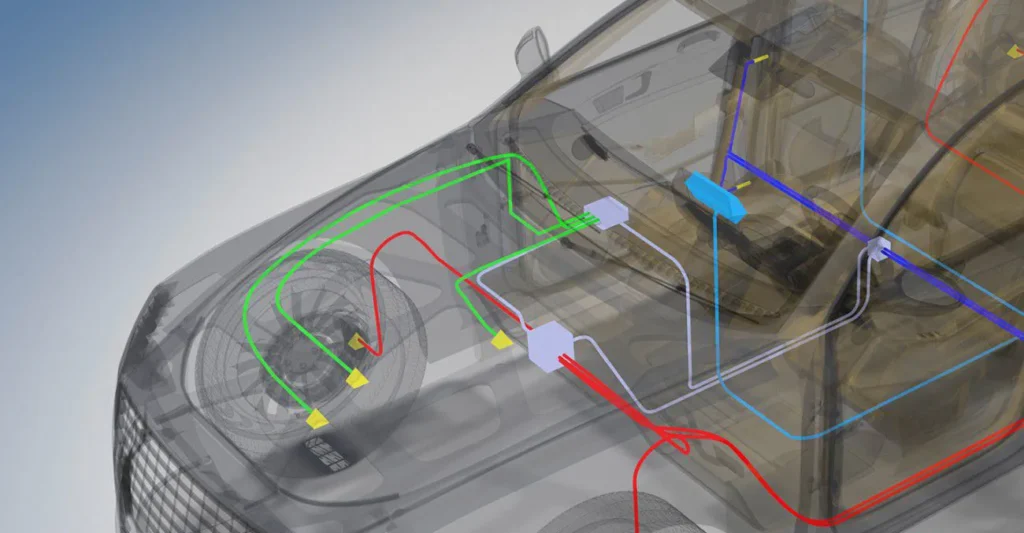

Drive Systems

Applications

- Electric Drive Units: Connectors are used for electrical connections between components within the electric drive unit, including the motor, gearbox, and control units.

- Sensor Connections: Connectors link various sensors (such as speed sensors and position sensors) to the control system, enabling precise control of the drive system.

Characteristics

- High Temperature and Corrosion Resistance: Drive systems often operate in high-temperature environments, requiring connectors with excellent temperature and corrosion resistance.

- High Durability: Connectors need to endure long-term use and high-load operation in drive systems.

On-Board Electrical Systems

Applications

- In-Car Electronics: Connectors are used for connecting in-car electronics such as displays, audio systems, and navigation systems, ensuring proper system operation.

- Control Panels: Connectors link various control panels, such as climate control and seat adjustment modules.

Characteristics

- High Stability: In-car electronics require stable electrical connections to ensure proper functionality.

- Ease of Maintenance: Connectors are designed for convenience in maintenance and replacement.

Vehicle Communication Systems

Applications

- On-Board Networks: Connectors are used for data transmission and network connections in various communication systems within the new energy vehicle, such as CAN bus and LIN bus.

- Information Transmission: Connectors facilitate the transmission of internal and external vehicle information, such as diagnostic data and driving data.

Characteristics

- High-Speed Data Transmission: Ensures the speed and accuracy of data transmission to support real-time information processing.

- High Reliability: Communication systems require connectors with high reliability to avoid data loss or transmission failures.

The rapid development of new energy vehicles brings higher technical requirements for automotive connectors. Choosing the right automotive connectors not only enhances the performance of new energy vehicles but also ensures their safety and reliability. As technology advances, automotive connectors will play an increasingly important role in new energy vehicles.