新能源汽车连接器根据功能和电压等级可分为三大类:

低压连接器

主要用于传统燃油车的BMS(电池管理系统)、空调系统、车灯等低压场景,工作电压通常低于60V。

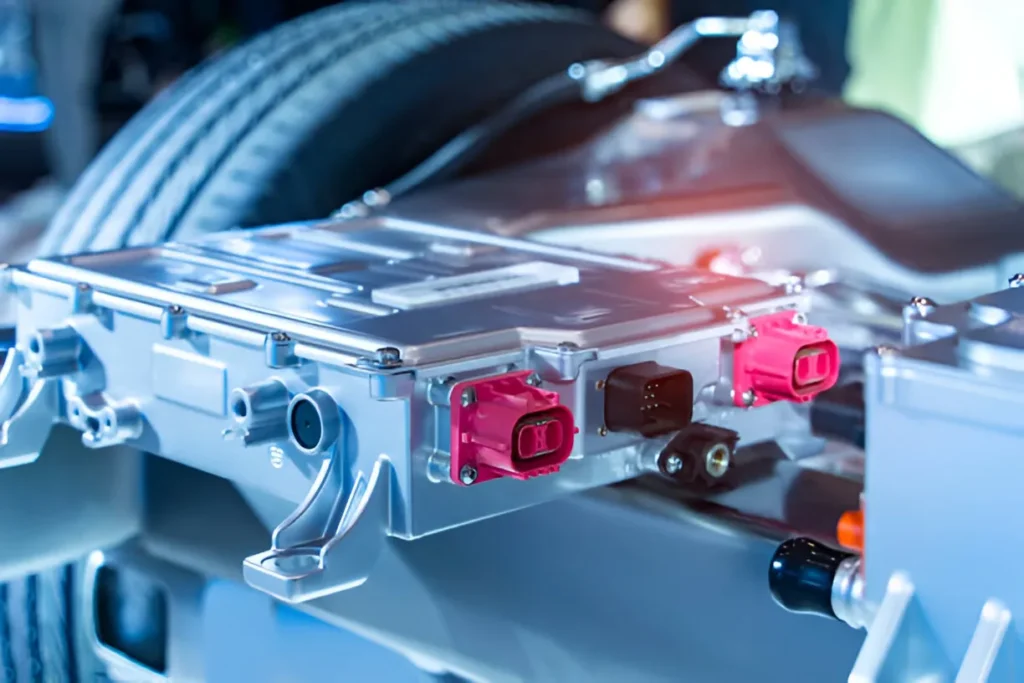

高压连接器

应用于新能源汽车的高压系统,如电池组、PDU(高压配电盒)、OBC(车载充电机)、DC/DC转换器、充电接口等,需承受400V~600V电压和50A~300A电流,部分场景甚至更高(如800V平台)。

典型产品:高压线束、充换电接口、液冷充电枪(如永贵电器的大功率液冷直流充电枪)。

高速连接器

支持智能驾驶和网联化需求,包括Fakra、Mini Fakra、HSD和以太网连接器等,用于ADAS传感器(摄像头、雷达)、信息娱乐系统和5G/V2X通信模块。

New energy vehicle connectors can be divided into three categories according to function and voltage level:

Low voltage connector

It is mainly used in low-voltage scenarios such as BMS (battery management system), air-conditioning system, and headlights of traditional fuel vehicles. The operating voltage is usually lower than 60V.

High voltage connector

The high-voltage systems used in new energy vehicles, such as battery packs, PDUs (high-voltage distribution boxes), OBCs (on-board chargers), DC/DC converters, charging ports, etc., need to withstand voltages of 400V to 600V and currents of 50A to 300A, and in some scenarios even higher (such as 800V platforms).

Typical products : high-voltage wiring harnesses, charging and swapping interfaces, liquid-cooled charging guns (such as Yonggui Electric’s high-power liquid-cooled DC charging gun).

High-speed connectors

Supports smart driving and networking needs, including Fakra, Mini Fakra, HSD and Ethernet connectors, etc., for ADAS sensors (cameras, radars), infotainment systems and 5G/V2X communication modules.

关键技术特点

高安全性与可靠性

防触电与防水密封:需满足IP67防水等级,压缩率设计在15%~27%以优化密封性能。

耐高温与抗电磁干扰(EMI):材料需耐受高压电弧和高温环境,如采用阻燃材料并优化电磁屏蔽设计。

耐久性与轻量化

新能源汽车连接器需适应长期振动和极端温度,材料选择以耐腐蚀、高强度为主(如铝合金或特种塑料)。

铝代铜趋势:铝导体因成本低(铜价约8万元/吨,铝价约3~4万元/吨)、轻量化(减重40%~50%)和资源丰富,逐渐替代铜导体。例如,中航光电的铝排产品已实现减重50%、降本30%~40%。

高速数据传输与智能化兼容

支持车载摄像头、雷达等传感器的高速信号传输(如中航光电的EVRF3系列产品降低串扰,提升可靠性)。

兼容智能网联需求,如以太网连接器和5G模块。

Key technical features

High security and reliability

Anti-electric shock and waterproof sealing: It must meet the IP67 waterproof rating, and the compression rate is designed to be between 15% and 27% to optimize the sealing performance.

High temperature resistance and anti-electromagnetic interference (EMI): The material needs to withstand high voltage arcs and high temperature environments, such as using flame-retardant materials and optimizing electromagnetic shielding design.

Durability and Lightweight

New energy vehicle connectors need to adapt to long-term vibration and extreme temperatures, and the material selection should be mainly corrosion-resistant and high-strength (such as aluminum alloy or special plastics).

Aluminum replacing copper trend: Aluminum conductors are gradually replacing copper conductors due to their low cost (copper price is about 80,000 yuan/ton, aluminum price is about 30,000-40,000 yuan/ton), lightweight (40%-50% weight reduction) and abundant resources. For example, AVIC Optronics’ aluminum busbar products have achieved a 50% weight reduction and a 30%-40% cost reduction.

High-speed data transmission and intelligent compatibility

Support high-speed signal transmission of on-board cameras, radars and other sensors (such as AVIC Optronics’ EVRF3 series products to reduce crosstalk and improve reliability).

Compatible with intelligent networking requirements, such as Ethernet connectors and 5G modules.

市场趋势与技术革新

高压快充推动技术升级

比亚迪发布的“兆瓦闪充”技术(1000V/1000A)加速了800V及以上高压平台的普及,推动连接器向更高载流能力、更小体积发展。

液冷充电枪和大功率铝排(如中航光电的Busbar)成为解决高压快充散热和布线限制的关键。

智能化与集成化

高速连接器需求增长,如Fakra系列用于环视系统,以太网连接器支持车载信息娱乐。

集成化设计(如PDU/BDU配电模块)简化系统复杂度,提升空间利用率。

国产替代与产业链协同

国内厂商如中航光电(市占率超30%)、永贵电器等逐步进入比亚迪、小鹏等头部车企供应链。

铝导体、自动化产线和耐磨镀层技术(如中航光电的超声波焊接和电镀工艺)成为国产技术突破重点。

新能源汽车连接器的技术迭代与市场扩张将持续推动行业向高压化、轻量化、智能化方向发展,成为支撑新能源汽车产业升级的重要基石。

Market trends and technological innovations

High-voltage fast charging promotes technology upgrade

The “Megawatt Flash Charge” technology (1000V/1000A) released by BYD has accelerated the popularization of high-voltage platforms of 800V and above, and promoted the development of connectors towards higher current carrying capacity and smaller size.

Liquid-cooled charging guns and high-power aluminum busbars (such as AVIC Optronics’ Busbar) have become the key to solving the heat dissipation and wiring limitations of high-voltage fast charging.

Intelligence and integration

There is growing demand for high-speed connectors, such as the Fakra series for surround view systems and Ethernet connectors to support in-vehicle infotainment.

Integrated design (such as PDU/BDU power distribution module) simplifies system complexity and improves space utilization.

Domestic substitution and industrial chain collaboration

Domestic manufacturers such as AVIC Optronics (market share over 30%) and Yonggui Electric have gradually entered the supply chains of leading automakers such as BYD and Xpeng.

Aluminum conductors, automated production lines and wear-resistant coating technologies (such as AVIC Optronics’ ultrasonic welding and electroplating processes) have become key areas of domestic technological breakthroughs .

The technological iteration and market expansion of new energy vehicle connectors will continue to drive the industry towards high pressure, lightweight and intelligent development, becoming an important cornerstone to support the upgrading of the new energy vehicle industry.