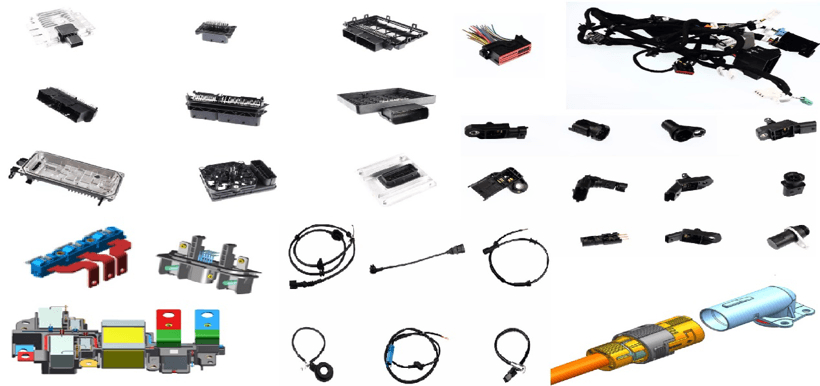

Understanding the various types of Automotive Connectors and their functions is crucial for anyone involved in vehicle maintenance or design. From pin and blade connectors to waterproof options, each type plays a significant role in ensuring the reliability and efficiency of modern vehicles.This article explores their functions and future trends.

Pin Connectors

Pin connectors are essential in the automotive sector, prized for their reliability and straightforward installation. These connectors feature a series of pins that fit into matching sockets, creating a secure link. They are frequently utilized in various electrical systems within vehicles, including lighting and engine management. A prime example is the pigtail connector automotive, which often employs pin connectors for quick and efficient connections between wiring harnesses and components.

Blade Connectors

Another widely used type is the blade connector, known for its flat, blade-like terminals. These connectors facilitate rapid connections and disconnections, making them suitable for automotive scenarios where maintenance is necessary. Blade connectors are available in different sizes to accommodate various wire gauges. For example, a 2 wire automotive connector typically uses blade connectors to securely join two wires while allowing for easy removal when needed.

Screw Terminal Connectors

Screw terminal connectors provide a sturdy solution for securing electrical links. They use screws to clamp down on wires, ensuring a strong mechanical connection that withstands vibration and environmental challenges. These connectors are particularly beneficial in high-current applications where dependability is crucial. Many automotive electrical connector kits include screw terminal connectors due to their versatility and durability.

Cylindrical Connectors

Cylindrical connectors cater to high-density applications, offering multiple connection points within a compact design. They are commonly found in intricate automotive systems where space is at a premium. Their cylindrical shape simplifies alignment and insertion, enhancing user-friendliness. Additionally, these connectors are available in both standard and waterproof versions, addressing various environmental needs.

Waterproof Connectors

In contemporary automotive design, waterproof connectors have become vital due to vehicles’ exposure to harsh conditions. These connectors are designed to block moisture ingress, safeguarding sensitive electrical components from corrosion and damage. A waterproof automotive connector is essential in areas like lighting systems and engine compartments where water exposure is common.

Future Trends in Automotive Connectors

As the automotive industry advances, so do the technologies associated with automotive connectors. Future trends point towards more compact and efficient designs that support electric vehicles (EVs) and advanced driver-assistance systems (ADAS). Innovations like smart connectors capable of transmitting performance and diagnostic data are gaining traction.

Furthermore, the demand for 3 wire connector automotive solutions is rising as vehicles require increasingly complex wiring systems to accommodate various electronic features. Manufacturers are also concentrating on creating automotive electrical connector kits that encompass a variety of connector types to satisfy diverse application requirements.

As automotive technology evolves, so do the connectors that facilitate electrical systems in vehicles. From pin and blade connectors to advanced waterproof options, each type plays a crucial role in enhancing vehicle functionality and safety. The future promises even more innovation in this vital area of automotive design.