Importance of Automotive connector

Automotive connector are key components of modern automotive electrical systems and play a vital role in ensuring reliable communication and power transmission between various vehicle systems. They not only provide a stable electrical connection, but also protect sensitive electronic components from environmental factors such as vibration, temperature changes and moisture. As the degree of automotive electronics continues to increase, the importance of high-quality connectors has become increasingly prominent, directly affecting the performance, safety and reliability of the vehicle.

Common Automotive connector types and their applications

Pin Connector

Pin connector are widely used in engine management systems, sensors, and lighting systems. This connector has a compact design and reliable connection performance, and can maintain stable operation in high vibration environments.

Blade Connector

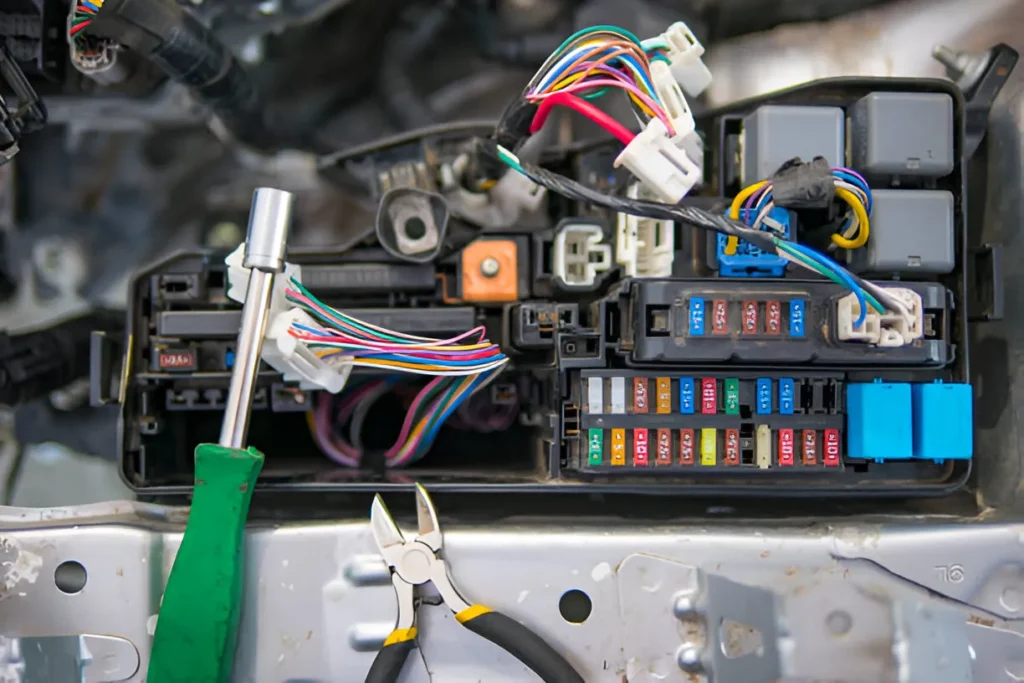

Blade connector are mainly used for components such as relays, fuses, and switches. Their design allows for quick plugging and unplugging, which is easy to maintain and replace while ensuring good electrical contact.

Screw Terminal Connector

Screw terminal connector are common in battery connections, grounding systems, and power distribution systems. This connector provides a strong mechanical connection and is suitable for carrying high current loads.

Barrel Connector

Barrel connector are mostly used in GPS, antennas, and audio systems. Their circular design helps to waterproof the seal and provide multi-pin connections in a limited space.

Waterproof Connector

Waterproof connector are specially designed for harsh environments such as outdoor and engine compartments, such as engine management systems. They can effectively prevent the intrusion of moisture and contaminants and protect sensitive electronic components.

Automotive connector Applications for Specific Vehicle Systems

Infotainment Systems

USB and Molex connectors are commonly found in infotainment systems. These connectors support high-speed data transfer and meet the needs of modern multimedia systems.

Engine Management Systems

Engine management systems typically use rectangular or square connectors. These connectors have a multi-pin design that can transmit multiple signals and power simultaneously.

Body Electronic Systems

Body electronic systems such as electric parking brakes, electric power steering, and electronic stability programs require specialized connectors that can withstand frequent vibrations and temperature changes.

Lighting Systems

Lighting systems include interior lighting and LED headlights, and the connectors used need to consider factors such as heat dissipation and moisture resistance.

Battery Management Systems

The on-board chargers in the battery management system use high-voltage connectors that need to have excellent insulation and safety features.

Considerations for choosing the right Automotive connector

There are several factors to consider when choosing an Automotive connector:

Vehicle type: Commercial vehicles and personal vehicles have different requirements for connectors, and the former usually require a more durable design.

Electrical area requirements: High-current and low-current applications require connectors of different specifications.

Environmental conditions: Factors such as temperature, humidity, and vibration will affect the choice of connectors, and the appropriate protection level needs to be selected according to the actual use environment.

The key role of Automotive connector in automotive electrical systems

Automotive connector play an indispensable role in modern automotive electrical systems. They not only ensure reliable communication between various subsystems, but also provide modularity and flexibility for the entire vehicle electrical system. High-quality connectors help improve the overall performance, reliability and safety of the vehicle, while also facilitating maintenance and upgrades. As cars move toward electrification and intelligence, connector technology is also constantly innovating to meet higher currents, faster data transmission speeds and stricter environmental requirements.