Over the past three decades, the rapid development of the automotive industry in China has spurred significant growth in the automotive wiring harness sector. This industry has transformed from non-existence to expansion, and from inception to maturity, showcasing a remarkable spiral of development. Today, China stands as the world’s largest automobile manufacturing nation, boasting the largest single-country automotive sales market. However, despite these achievements, the development of domestic automotive brands and their core components still falls short of elevating China to the status of a major automotive power.

Early Reliance on Imports and Technology Assimilation

For a prolonged period, the Chinese automotive industry relied heavily on the importation and assimilation of production processes and technologies from leading global automotive conglomerates. This approach was crucial for fostering growth within the industry. The trajectory of the automotive wiring harness industry closely mirrored that of the broader automotive sector, which can be classified into three distinct phases.

The Initial Phase: The Era of Self-Reliance

The initial phase of the automotive wiring harness industry coincides with the era of self-reliance within China’s automotive sector during the planned economy period. This stage also marks the infancy and growth phases of the auto industry in China. During this time, the government implemented a planned economy, resulting in rapid advancements in the automotive sector. However, the overall level of automotive technology remained significantly underdeveloped, so much so that the wiring harness industry could not yet be recognized as an independent segment within automotive components. Despite the swift progress, the technological capabilities in the automotive manufacturing realm remained rudimentary, characterized by straightforward vehicle configurations and limited production volumes.

Governmental Views and Early Automotive Developments

During this period, state industrial departments generally viewed passenger cars as luxuries for the bourgeoisie, while trucks were considered utilitarian vehicles predominantly for transportation. Tractors, on the other hand, were deemed genuine necessities for the working populace. Consequently, the limited indigenous passenger cars and imported vehicles primarily served governmental purposes. As a result, the technical proficiency of the passenger car industry languished in a nascent stage for an extended duration. The two-stroke engine three-wheeled trucks and Jiefang-branded trucks were among the most ubiquitous participants in China’s road traffic landscape at the time.

Milestones in China’s Automotive Industry

July 15, 1953, marked the foundation of the First Automobile Manufacturing Plant in Changchun, leading to the debut of China’s first domestically produced Jiefang brand trucks from the assembly line on July 14, 1956. This batch of twelve vehicles of type CA10 signified the end of the era wherein China could not manufacture automobiles autonomously. The year 1958 stands as a crucial milestone in the history of Chinese passenger car development. In April 1958, the first domestically produced car, the CA71 Dongfeng sedan, successfully navigated trials at the First Automobile Manufacturing Plant, embodying Chairman Mao Zedong’s famous assertion about the global balance of power: “the east wind prevails over the west wind.” That same year in August, China’s first standardized passenger car, the Hongqi CA72 luxury sedan, rolled off the production line, while both the Beijing Automobile Factory and Shanghai Automobile Factory produced their own models—the Jinggangshan and Fenghuang brands, respectively—alongside the success of the Chongqing Arsenal in creating the Yangtze No. 46 jeep.

Expansion and Technological Renovations

By 1965, an astounding investment of 1 billion yuan had been funneled into China’s automotive industry, leading to the establishment of a large-scale manufacturing facility comprising four major factories and several smaller entities. These facilities produced approximately 60,000 units annually, contributing to a total vehicle ownership of about 290,000 in China, of which 170,000 were domestically produced. The automotive industry began to explore the production of military off-road vehicles post-1964, adhering to central directives. Noteworthy developments included the second automobile manufacturing plant, the Sichuan Automotive Industry Group Company, and the Ouxi Automotive Holdings Group Company, which concentrated on the production of medium and heavy-duty trucks alongside off-road vehicles, further diversifying into mining dump trucks.

During this time, primary manufacturing bases—such as the First Automobile Manufacturing Plant, Nanjing Automobile Group Co., Beijing Automotive Group Co., Shanghai Automotive Group Co., and Jinan Automotive Manufacturing Plant—invested persistently in technological renovations and capacity expansion. These efforts supported the establishment of more local automotive manufacturers, eventually leading to nearly 200 automotive and modification plants that largely replicated major domestic automotive models.

The Rise of the Shanghai Sedan and the Role of State-Owned Enterprises

Between 1966 and 1980, the national output of various automotive types reached a cumulative total of approximately 1.639 million units, with 1.48 million being trucks. In 1964, the Shanghai Automobile Factory rebranded the Fenghuang sedan to the Shanghai sedan while implementing numerous improvements to the manufacturing apparatus. This included the production of simplified molds for body parts, which marked a pivotal transition from a wholly manual and outdated assembly approach to a more modernized production line. With this revamped process, the Shanghai sedan’s quality gradually stabilized and improved. By 1965, the Shanghai sedan passed technical evaluations by the Ministry of First Mechanical Industry, emerging as the second model in China—after the Hongqi—to achieve mass production approval. This model ultimately yielded over 17,000 units by 1979, establishing itself as one of the primary models for government use and taxi services.

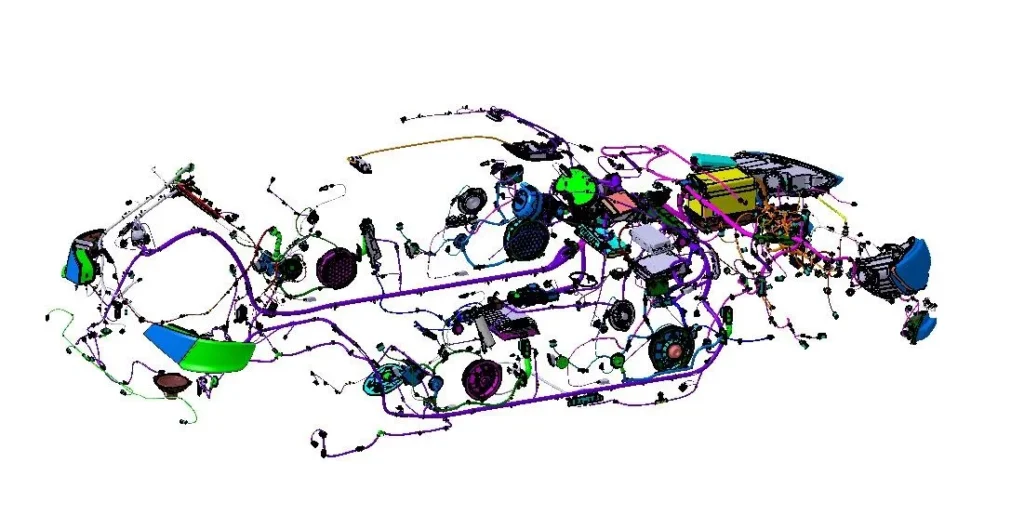

The Early Stages of the Automotive Wiring Harness Industry

During the initial phase of the automotive wiring harness industry, the processing of wiring harnesses was generally carried out by subordinate factories of major automobile manufacturing plants, along with a limited number of state-owned automotive component enterprises. For instance, during the assembly of Jiefang brand trucks, the Changchun Bulb Factory began supplying wiring harnesses. However, design and production were primarily manual, with the concept of the wiring harness being nebulous. At this stage, the wiring harness industry could not be categorized as a distinct automotive component sector. The technical attributes of automotive wiring harnesses during this period can be summarized as follows:

- Basic Electrical Connections: The electrical connection methods for wiring harnesses were rudimentary, predominantly relying on simple contact structures such as bolt-connected terminals.

- Simple Electrical Components: Automotive electrical components were basic, aimed only at ensuring the fundamental functions of vehicles. These included direct current generators, simple incandescent bulbs for illumination, turn signals, push-pull switches, contact-based ignition devices, mechanical water temperature sensors, oil pressure sensors, and odometers with flexible cable systems. Apart from a few select models with large radios, vehicles offered minimal entertainment electronics.

- Basic Design Objectives: The primary goal of wiring harnesses was to facilitate connections among electrical components, satisfying basic conductive performance and integration strength requirements. Other specifications, such as electromagnetic interference resistance, voltage drop, signal stability, and vehicle safety, remained relatively ambiguous.

- Manual Assembly Processes: Connections between wires were typically insulated with electrician’s black tape, and wires were often secured in vehicles using metal-clad plastic tubing to prevent mechanical damage and friction during operation.

- Prototyping and Design: The design methodology for wiring harnesses involved first simulating working conditions to create prototypes, followed by physical verification before finalizing production process diagrams. The design diagrams for the automotive electrical systems merely illustrated physical connections between electrical components, offering limited visualization of circuit operational principles.

- Low Mechanization: The degree of mechanization in wiring harness processing was notoriously low, with nearly all operations—including wire cutting, crimping, welding, and bundling—performed manually. The assurance of product quality heavily relied on the skills of the workers, resulting in significant inconsistencies in product quality.

Conclusion

The journey of China’s automotive wiring harness industry from its inception to its current state reflects the broader evolution of the Chinese automotive industry. Although the industry started from a rudimentary phase with limited technological capabilities, it has grown and matured alongside the automotive sector. While challenges remain, the industry’s development has laid a solid foundation for future advancements, as China continues its pursuit of becoming a major automotive power.