With the widespread adoption of digital engine management systems in the 1980s, vehicle chassis wiring harness design faced new challenges. These challenges primarily stemmed from the need to accommodate digital signal transmission and highly sensitive analog sensor signals. Although cost-effective, the use of PVC as an insulating material introduced complications due to its high dielectric constant.

Limitations of PVC Insulating Material

The dielectric constant is an indicator of a material’s polarization capacity under an electric field. Materials with high dielectric constants tend to absorb more energy, which can lead to signal attenuation and distortion at high frequencies. Additionally, signal lines needed to operate within the electromagnetic interference environment created by ignition and charging systems while suppressing crosstalk among internal harness circuits. Consequently, low dielectric constant insulating materials such as polyethylene and cross-linked polyethylene emerged as superior alternatives, as they minimized signal loss at high frequencies, particularly suitable for transmitting sensitive signals like those from ABS sensors or NOx sensors.

Integration of Electronic Systems and Network Topologies

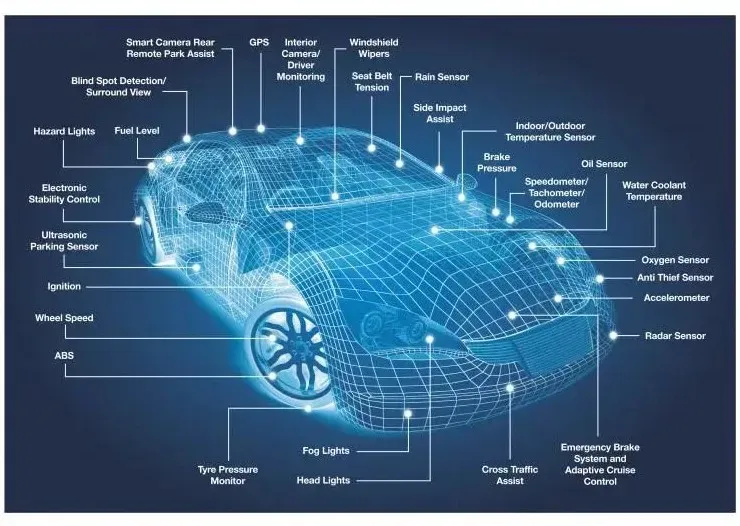

In the 1990s, with the integration of computer technology, automotive electronic systems began to converge with network topologies, gradually adopted by most automotive manufacturers. In this architecture, each vehicle subsystem was equipped with electronic control units, while multiplex signal protocols enabled the exchange of multiple data streams over a single physical channel.

The initial multiplexing systems utilized basic serial communication protocols derived from industrial fields, such as RS-232, RS-485, and RS-422. These protocols operated based on preset fixed baud rates and necessary connection management data to facilitate direct bit stream transmission. The simplest form involved single-ended communication, characterizing bits through voltage levels relative to ground. Although this method required only a single signal line, making it straightforward to implement, it was limited by its high sensitivity to noise, which constrained the bit rate.

Advantages of Differential Serial Communication

In contrast, differential serial communication improved upon this by employing a dual signal line configuration, where one line transmits the positive signal and the other transmits the inverted signal. As noise affects both signals equally along the transmission line, the receiver can effectively eliminate interference by subtracting the inverted signal from the positive signal. This technology significantly enhanced resistance to interference and enabled high-speed, reliable transmission over longer distances compared to single-ended serial communication.

Introduction and Adoption of CAN Bus Protocol

In the early 1980s, various serial communication protocols emerged in the automotive industry, including L-LINE 1850 based on pulse-width modulation, while General Motors adopted the SCI protocol. Although these early protocols facilitated vehicle diagnostics and inter-module communication, they remained inadequate in terms of transmission speed and flexibility.

In 1986, at the Society of Automotive Engineers conference in Detroit, Michigan, Bosch introduced the Controller Area Network (CAN) bus protocol. This was designed as a multi-master serial data bus that allows multiple nodes to engage in interference-free, highly reliable data exchange over a single channel. It transmits differential signals using a pair of transmission lines, effectively filtering out noise interference. Furthermore, the CAN protocol defines an information encapsulation mechanism, packaging interaction information between modules into data frames while offering advanced features such as priority transmission and error detection.

By the mid-1990s, the industry had widely accepted the initially introduced 8-bit analog-to-digital converter as the standard for vehicle digital communication. Over time, this standard continued to evolve to meet demands for higher-speed data transmission and greater load capacity.