When dealing with electrical systems, the integrity of the connection is essential, whether it is to repair a vintage car or to build a custom robot project. At the core of these connections, there is a small but important component: the female terminal. Although it seems to be just a simple piece of metal, choosing the right terminal and the correct installation can effectively ensure that the system can run smoothly for many years, and can distinguish the fault caused by vibration or corrosion.

In this article, we will explore the world of electrical connectivity. We will analyze in detail what is the female terminal, why we should pay attention to the quality of the automobile female terminal, and how to master the process of crimp terminal.

What Is a Female Terminal?

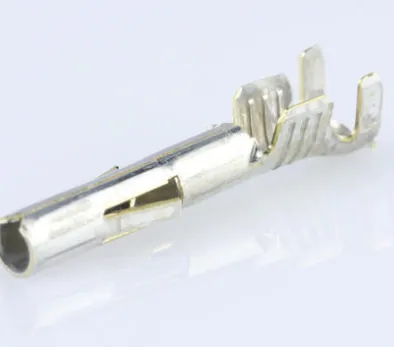

The female terminal is an electrical contact device designed to receive and lock matching ‘male’ inserts or pins. Different from the public connector as a plug, the female terminal acts as a socket. It is usually designed with a spring-like mechanism (usually referred to as a spring or shutter structure) that applies sustained pressure to the male pin to ensure continuous current flow.

Why Are They So Important?

In any wiring harness, the fault point is rarely the wire itself, and almost always the terminal connection point. Poor quality of the female terminal may lead to :

High Resistance: Cause voltage drop, dim light or sensor error.

Heat Generation: Resistance generates heat, which may melt the connector housing.

Intermittent Failures: Loose connections that rattle apart under vibration.

The Anatomy of a High-Quality Automotive Female Terminal

Not all terminals have the same quality. When purchasing vehicle maintenance parts, the automotive female terminal usually has a specific function to withstand harsh environments.

Material Composition

Most standard terminals are made of brass. However, high-performance automotive terminals usually use Phosphor Bronze or Beryllium Copper. These materials provide excellent spring performance, ensuring that the terminal can still hold the male pin tightly even after years of engine vibration.

Coating Type

Tin Plating: The standard for most automotive applications. It provides good corrosion resistance and electrical conductivity.

Gold Plating: Used for low voltage sensor signals such as ECU pins, because even a slight corrosion can change the data reading. Gold does not corrode (oxidize).

Locking Mechanism

A qualified master terminal includes a locking shrapnel (a small metal wing). When the plastic connector shell is inserted, the spring clip will be stuck in place to prevent the wire from being pulled out from the back of the plug.

DEZHOU TIANDIAN Tip: Be sure to check whether your connector housing requires ‘Primary Lock’ (on the terminal) or ‘Secondary Lock’ (a plastic wedge on the housing).

Crimp Terminal vs. Solder Terminal: Which is Better?

A common debate in the DIY community is whether to weld or crimp. In the context of automotive and industrial wiring, cold-pressed terminals are scientifically superior.

The Physics of Crimping

When the cold-pressed terminal is compressed on the wire with sufficient force, ‘ cold welding ‘ will be achieved. The metal of the terminal and the copper strand of the wire are deformed together to form an airtight seal. This prevents oxygen from entering and corroding the connection.

Crimping Pros: Flexibility (vibration resistance), high consistency, good air tightness.

Soldering Cons: Brittle (easy to break under vibration), solder will suck along the wire core (produce stress points), the process is slow.

How to Crimp a Female Terminal Correctly?

Correct technology is needed to achieve factory-level crimping. Please follow the following steps to ensure that your female terminal is securely fixed.

Tools Required

High quality crimping pliers (recommended ratchet type).

- Stripping clamp.

- Correctly sized wires and terminals.

Step-by-Step Installation Guide

1. Strip the Wire: strip off an appropriate amount of insulation layer, so that the copper strand is located in the conductor crimping area, and the insulation layer is located in the insulation crimping area. Usually 3mm to 5mm is enough.

2. Place the Terminal: Before inserting the wire, put the female terminal into the jaw of the crimping tool.

3. Insert the Wire: Slide the wire into the terminal. Ensure that the copper strand does not extend to the matching area (where the male pin enters).

4. Crimp: Extrude the ratchet tool until it is automatically released. This tool ensures that the right amount of pressure is applied.

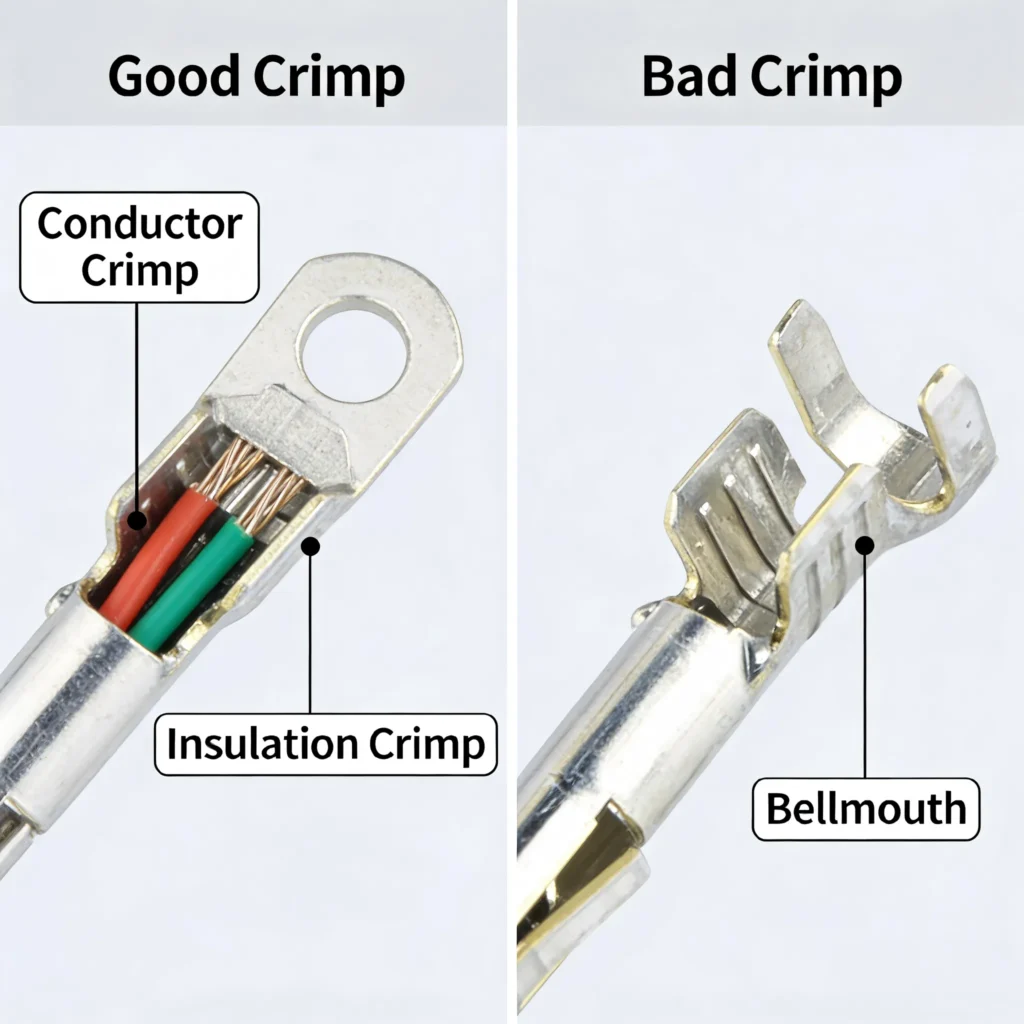

5. Check the Crimp:

- Conductor Crimp Wing: should be tightly folded on the bare copper ‘core’.

- Insulated Crimp Wing: The colored insulation layer should be tightly wrapped to provide stress relief.

- The ‘Bellmouth’: There should be a slight flaring at the rear of the crimp to prevent sharp metal from cutting off the wire strands.

Types of Female Terminals by Application

Here are common types:

- Open Barrel Terminals: The most common automotive female terminal. They have ‘wings’ that are pressed down.

- Closed Barrel (Ring/Fork) Terminals: Usually insulated with PVC or nylon heat-shrinkable pipe. Used for grounding or connecting the battery column.

- Bullet Connectors: Cylindrical female terminals commonly used in old motorcycles and classic cars.

- Spade/Disconnect Terminals: Flat female connectors for relays and speakers.

| Comparison Table: Female vs. Male Terminals | ||

|---|---|---|

| Feature | Female Terminal | Male Terminal |

| Shape | Socket/Receptacle | Pin/Tab |

| Function | Grips the pin; Provides tension | Inserts into socket; Static |

| Wear Factor | High (Spring tension can fade) | Low (Solid metal) |

| Protection | Often fully recessed in housing | Often exposed pins (when unplugged) |

Troubleshooting Common Issues

If you encounter an electrical fault, the female terminal is the primary suspect.

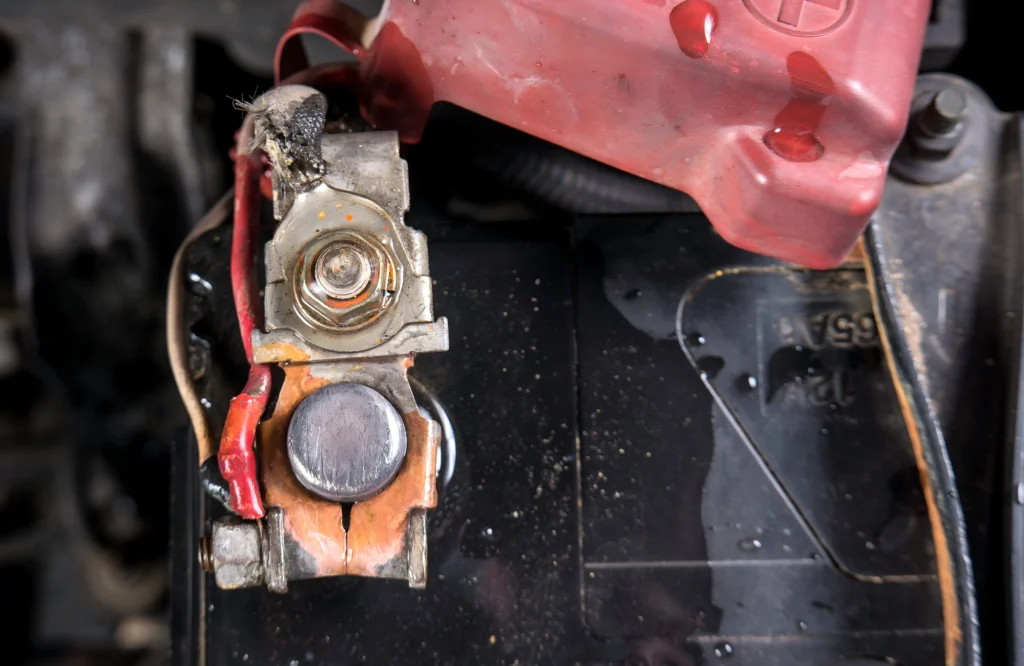

Why did my connector melt?

This is caused by high resistance. If the female terminal loses the spring tension (clamping force), the contact area will be reduced. The smaller the contact area means the higher the resistance. As the current flows, heat will accumulate.

Solution: Replace the terminal immediately. Don’t just clean it; the metal may have lost tempering (strength).

Why can’t the terminal stay in the plug?

You may flatten the locking spring during the crimping process, or insert it upside down.

Fix: Use the needle picking tool to gently bend the locking plate back, and then re-insert it into the connector shell.

Conclusion

Whether you’re building a custom ECU harness or just fixing a damaged taillight, you need to understand the mechanism of these connectors. By choosing the right car female terminal, using the right cold-pressed terminal technology, and understanding the materials involved, you can ensure that your project remains safe, conductive and reliable over the long term.

Don’t cut corners on the connection. By investing in high-quality terminals and the right tools, your cabling system will be more stable.

A lot of the time, you don ‘t need to cut the wire, you need to use the depinning technique. The reason why the female terminal is locked in the plastic shell is that it has a tiny metal locking Tab on the back or bottom.

Operation method: Do not pull the wire hard, which will break the wire core. You need to insert a dedicated terminal removal tool or a very thin hard needle (such as a paper clip or a sewing needle) from the front end of the connector (insertion port).

Trick: gently press down the metal barb to make it flat, while gently pulling the wire from the rear, the terminal will slide smoothly.

Using a pointed jaw pliers, gently press down the top of the crimp part of the parent terminal. This can restore its clamping force.

If the terminal has been severely corroded or metal fatigued (no elasticity after pressing), the repair is only temporary, and it is recommended to cut directly and re-press a new terminal.

Re-crimping is not allowed.

The crimping process will cause permanent deformation (cold deformation) of the metal. Once you forcibly pry open the crimp wings to try to put in new wires, the metal structure will become very fragile and will not be able to provide sufficient grip again, which will cause excessive resistance.

The terminal melting is almost always caused by the heat generated by the high resistance, rather than the external environment heat. Common causes include:

Bad Crimp: There is a gap between the copper wire and the terminal, and the arc and heat are generated when the current passes through.

Loose Fit: the mother terminal is too loose to tightly clamp the male insert, and the contact surface is too small to cause overheating.

Overloading: The current exceeds the rated load capacity of the terminal or wire.

Troubleshooting: If signs of melting are found, do not only replace the plastic shell. The damaged wire segments must be cut off and the new terminals must be re-pressed using high-quality crimping tongs.