Automotive wiring harnesses are like the “neural network” of a vehicle, and their design quality is directly related to the safety and stability of the vehicle’s electrical system. So, how is this key “neural network” designed and manufactured? What key materials are involved in the selection ?

Basic process of wiring harness development and design

- Requirements integration and confirmation: Engineers list all electrical devices that need to be connected according to the vehicle function list, confirm the functional details with relevant engineers, obtain interface information, and form an electrical schematic layout diagram. After integrating the principles of each ECU system, draw a complete wiring harness schematic diagram, and focus on checking the current requirements of each circuit (especially high-power equipment such as motors) to ensure that the operating requirements are met.

- 3D layout first: Use CATIA or UG and other software to design the initial 3D wiring diagram according to the wiring harness processing technology. At this stage, the fuse box position needs to be preliminarily determined, and adjustment space should be reserved for the wiring harness direction.

- 2D drawing conversion: Convert 3D designs into 2D engineering drawings that comply with industry standards (such as QC29106).

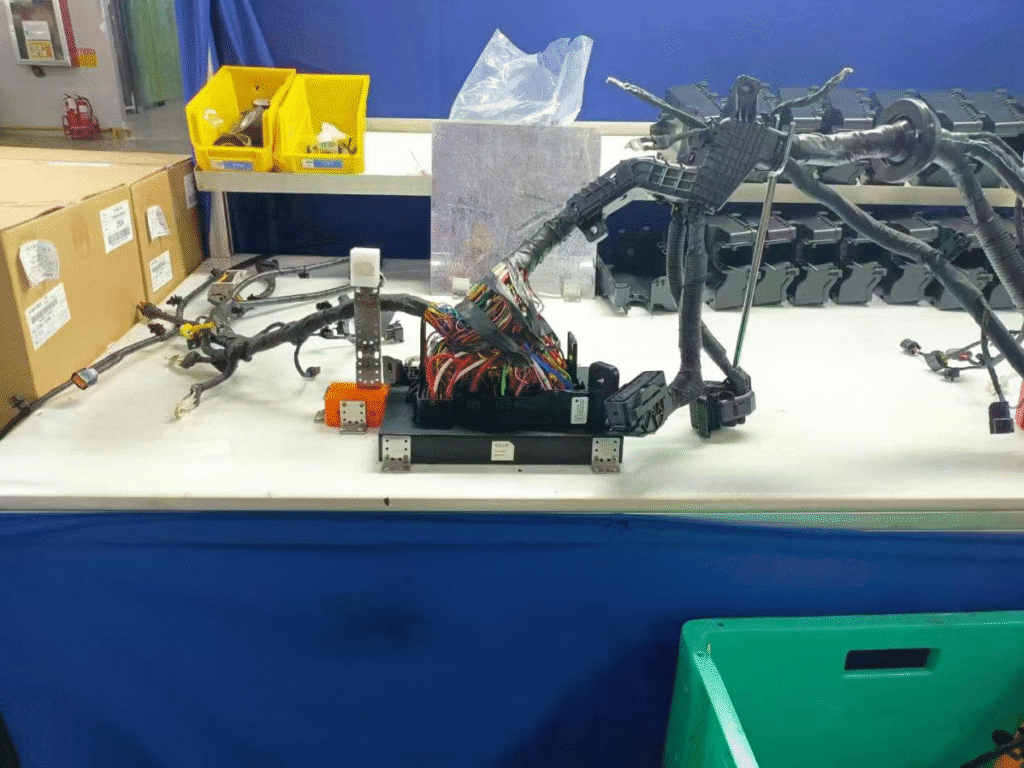

- Sample production and trial assembly: Make manual samples based on 2D drawings and conduct the first trial assembly in the actual vehicle.

- Dynamic optimization: Based on the results of trial installation and trial operation, 3D wiring engineers will make fine adjustments to the direction and length of the wires, taking into account the dynamic changes during vehicle driving.

- Continuous iteration: The wiring harness design needs to be coordinated with the installation requirements of the vehicle and various electrical systems, and continuously optimized and updated throughout the development cycle.

Parts selection

Wire

The first thing to consider is the function and environment that the wiring harness needs to achieve.

High temperature and high corrosion areas (such as engine compartment): select high temperature resistant and oil corrosion resistant materials (such as Teflon, cross-linked PE).

Frequently bending areas (such as car doors and trunks): elastic materials (such as TPE and rubber) are preferred.

Weak signal transmission (such as knock sensor): composite shielded wire must be used.

Cab: You can choose PVC wiring harness which is low-cost and lightweight.

Connectors

The connector is the most important component of the wiring harness. It directly determines whether the wiring harness can achieve the most core connection function and plays a decisive role in the stability of the electrical system.

Selection requirements for connectors

Ensure reliable matching with electrical components, meet mechanical plug-in and pull-out force standards, and give priority to using a secondary lock structure. The contact resistance must be low, and the insulation resistance and overcurrent capacity must meet the wire requirements. Wet area applications must be equipped with waterproof sheaths and corresponding seals to meet the regional waterproof level.

Connector raw material properties

①Sheath material (plastic parts):

Commonly used engineering plastics such as PA66, PBT, ABS, etc. are modified by adding glass fiber (to enhance strength) and plasticizer (to increase flexibility).

②Terminal material (copper):

Mainly use brass (wear-resistant), bronze (good casting, stability) or copper alloy (good electrical and thermal conductivity, ductility and corrosion resistance). To resist salt spray aging, the terminal surface needs to be tinned, gold-plated, etc.

Connector Classification

According to the connector pairing form, it can be divided into: wire-to-wire and wire-to-board.

①Line to line

Wire-to-wire connections include wire-to-cable or cable-to-cable forms, and their defining feature is that two individual wires or corresponding conductors in two cables are permanently connected to each other.

②Wire-to-board

The wire-to-board connection is mainly a connection in which the connector at one end is connected to the wire or cable, and the terminal on the other end of the connector is fixed and welded to the substrate.

Wire harness “armor”: covering material is crucial

In order to resist long-term damage such as oil, dust, friction, moisture and rust, and avoid functional failure caused by disconnection and short circuit, the wiring harness needs to be reliably wrapped and protected:

Bellows (core protection)

The corrugated tube is the most important wire harness protection material used in automotive wiring harnesses, and is generally divided into single-sided opening and sealed sleeves.

There are two types: open type and sealed type. The main materials are PE, PA, PP, etc., and the temperature resistance range covers multiple levels from -40°C to 150°C. PA has excellent flame retardancy and wear resistance, and PP has good bending fatigue resistance.

Adhesive tape (the most widely used)

PVC tape: good insulation, temperature resistance of about 80-105°C, harder wiring harness, average noise reduction.

Flannel tape (PET-based): temperature resistance of about 105°C, good noise reduction, and soft wiring harness.

Braided network tube

Cloth-based tape (PET-based): The best wear resistance (up to D/E grade), temperature resistance of 150°C, often used for vias or places with relative movement, and the price is relatively high.

It is woven from PA66 or PET monofilament and is available in open and closed types. It has excellent wear resistance but relatively high cost and noise. It is suitable for long-term motion parts.

The design and selection of automotive wiring harnesses is a comprehensive skill that integrates electrical principles, material science and precision manufacturing. From precise current calculation to ingenious layout in three-dimensional space, from careful selection of weather-resistant materials to foolproof connection interfaces, every step is related to driving safety and experience. With the advancement of the wave of automotive intelligence and electrification, the design of this “nerve network” will face higher requirements, and its innovation and optimization will never end.