How Do Male and Female Terminals Work Together

Male and female of automotive wiring terminals are important components to ensure connectivity in various vehicle systems and applications. Together, male and female terminal form a reliable connection system. When the pin of a male terminal is inserted into the socket of a female terminal, the circuit is completed, enabling seamless power or signal flow. To enhance performance under challenging conditions like vibrations or extreme temperatures, many connectors include locking mechanisms or advanced designs like hyperboloid contacts.

What is an Automotive Male Terminals?

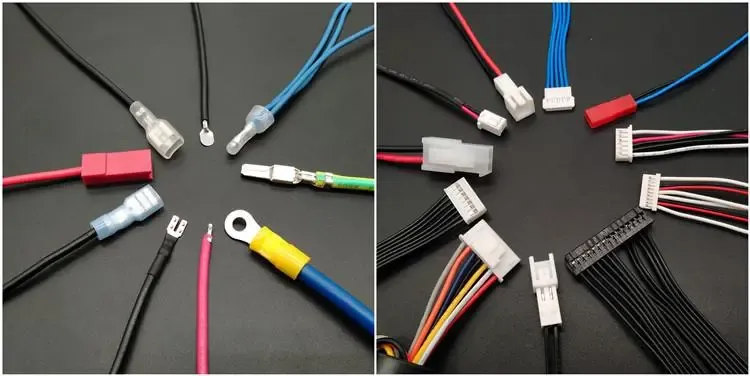

An automotive male terminal, often called a “plug,” is a projecting component used to create electrical connections in a vehicle’s system. It typically includes pins or blades that fit securely into matching female terminals. Made from conductive materials like copper or brass, male terminals ensure effective power and signal transmission. Their design emphasizes durability and ease of use, making them essential for various automotive systems such as lighting, sensors, and infotainment setups.

Male automotive wiring terminals come in different forms—round, flat, or square—depending on their application. For instance, they are commonly found in headlight or audio system connectors. However, their exposed pins make them vulnerable to damage if handled improperly.

What is an Automotive Female Terminals?

The female terminals, or “socket,” complements the male terminal by receiving its pins. It features a recessed structure that securely holds the male terminal in place, ensuring stable electrical connections. Slightly larger than male terminals to facilitate insertion, female terminals are often insulated externally while maintaining a conductive metallic interior for efficient performance.

Female automotive wiring terminals are widely used in fuse boxes, safety systems like airbags, and comfort features such as heated seats. Their design protects against dust and moisture while reducing the risk of accidental disconnections. However, regular maintenance may be needed to prevent debris buildup inside the socket.

Male and female of automotive wiring terminals Advantages and Disadvantages

Male Terminal:

- Advantages: Easy alignment and connection; compact design; resistant to debris accumulation.

- Disadvantages: Exposed pins are prone to damage; limited protection against moisture.

Female Terminal:

- Advantages: Protective design reduces pin damage; resists environmental contaminants; ensures stable connections.

- Disadvantages: Requires maintenance to avoid debris buildup; slightly bulkier than male terminals.

Key Differences Between Male and Female Terminals

| Feature | Male Terminals | Female Terminals |

|---|---|---|

| Design | Protruding pin/blade | Recessed socket |

| Primary Role | Initiates connection | Receives connection |

| Size | Generally smaller | Slightly larger |

| Durability | More prone to damage | Better environmental protection |

Applications in Vehicles

Automotive male and female terminals are vital across various systems:

- Power Distribution: Found in fuse boxes for efficient energy transfer.

- Safety Systems: Used in airbags and anti-lock braking systems.

- Infotainment Systems: Enable connections for screens and audio devices.

- Engine Components: Support sensors and other critical parts.

For example, male terminals connect directly to bulbs in lighting systems, while female terminals link these connections to the power source. Similarly, in airbags, female sockets ensure secure connections that withstand operational vibrations.

How to Choose the Right Automotive Terminals

Selecting the correct terminal involves considering:

- Application Needs: Quick-disconnect designs for frequent disassembly or screw-down terminals for permanent stability.

- Environmental Factors: Female terminals offer better protection against dust and moisture.

- Material Selection: Tin-plated copper provides corrosion resistance; gold plating ensures high conductivity.

- System Compatibility: Ensure the terminal’s size and shape match existing components.