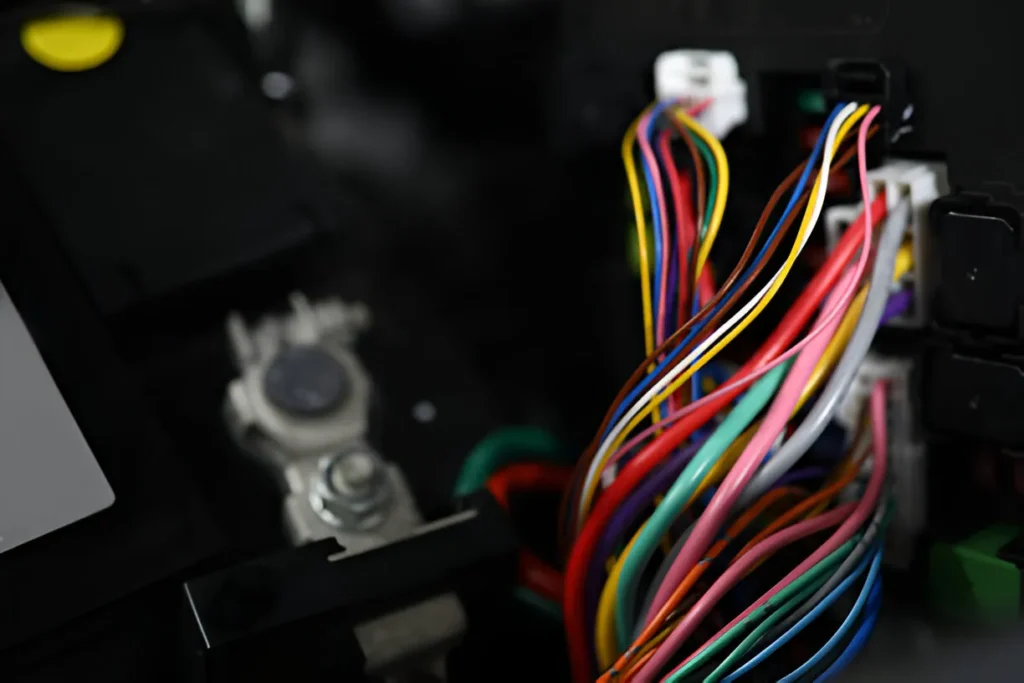

Main functions of automotive connectors

Automotive connectors act as a bridge in the circuit, connecting blocked or isolated circuits, allowing the current to flow smoothly and realizing the intended function of the circuit. They are mainly composed of contacts, housings, insulators and accessories. The contacts are the core components, and the electrical connection is completed by the insertion of the positive and negative contacts. The housing provides mechanical protection and ensures the alignment of the plug and socket. The insulator arranges the contacts and ensures their insulation performance, while the accessories include sealing rings, etc., which are used to enhance the function and stability of the connector26.

Installation steps

When installing automotive connectors, the following steps should be followed:

- Preparation: Make sure all tools and materials are ready, and check the integrity of the connector and its accessories.

- Positioning: Align the connector with the socket and ensure the correct direction.

- Insertion: Gently push the connector to fully insert it into the socket until you hear a locking sound.

- Locking: Check whether the locking device is properly fixed to prevent loosening.

- Testing: After completing the installation, perform an electrical test to ensure that the connection is normal3.

Daily maintenance and replacement

Daily maintenance includes regular inspection of the connector’s appearance and function, removal of surface dirt, and ensuring that it remains dry and clean. If the connector is found to be worn or corroded, it should be replaced in a timely manner. When replacing, it is necessary to select products that match the original specifications and follow the correct steps for disassembly and assembly to avoid damage to other components57.

Protective measures for automotive connectors housings under high temperature conditions

Under high temperature conditions, the following measures need to be taken to protect automotive connectors:

Material selection: Use high temperature resistant materials such as engineering plastics and metals to improve heat resistance.

Environmental control: Avoid long-term exposure to extreme high temperature environments, and add heat dissipation devices when necessary.

Regular inspection: Monitor connector temperature changes to prevent ablation or failure due to overheating4.

What are the common faults under use?

Common faults of automotive connectors include:

- Friction corrosion fault: caused by high humidity, corrosive gases and vibration, resulting in oxidation of the contact surface.

- Electrical fault: poor connection between the cable and the terminal, resulting in interruption of signal transmission.

- Connection fault: loosening or falling off due to improper operation or lack of locking device110.