When you’re working on a project that involves electronics, the choice of connectors can make or break your design. A 2 pin connector may seem like a small piece of the puzzle, but it plays a vital role in ensuring your circuit works as intended. Whether it’s powering a small appliance, linking parts in a machine, or even supporting communication in a device, getting the right connector is crucial.

1. Understanding Connector Requirements

Before diving into the world of 2 pin connectors, it’s essential to know what you need. The right connector will depend on several key factors, like power needs, signal requirements, and the environment in which it will be used.

Power, Signal, and Environmental Needs

- Power Requirements: What voltage and current does your project demand? For example, a simple battery-powered gadget will require a much lower power rating compared to an industrial machine.

- Signal Types: Do you need the connector to carry just power, or will it also be responsible for data or signals? Analog and digital signals require different handling to avoid interference or data loss.

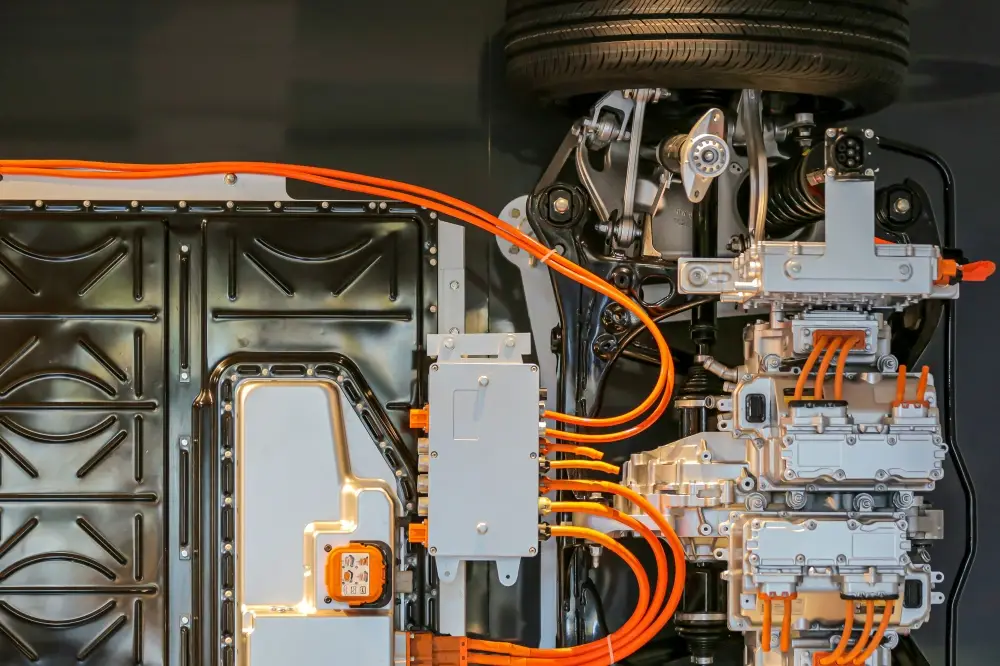

- Environmental Considerations: Will your connector be exposed to moisture, dust, or extreme temperatures? For example, automotive connectors are designed to withstand vibration and exposure to elements, whereas indoor applications might not require such rugged designs.

Key Considerations

- Voltage and Current Ratings: Make sure the connector’s electrical specifications align with your project’s needs. If you’re using it in a high-power system, you’ll need a connector rated for higher voltage and current.

- Signal Type Compatibility: Whether it’s just a power connection or a mixed signal and power connection, ensure the connector type can handle your specific needs.

- Operating Conditions: Environmental factors like moisture, extreme temperatures, or vibrations can affect the performance of connectors, so choose one that is suited for your working conditions.

By carefully assessing these factors, you’ll have a clearer idea of what you need from your 2 pin connector, which will help you narrow down your options.

2. Connector Types and Features

There are many types of 2 pin connectors, each designed for different applications. Understanding these types will guide you to the one that fits your specific needs.

Key Types of 2 Pin Connectors

- PCB Connectors: These are used when connecting two printed circuit boards (PCBs). If you’re designing a device that requires multiple internal components to communicate, PCB connectors might be your best bet.

- Wire-to-Wire Connectors: This is one of the most common types of connectors used in everyday electronics, from home appliances to automotive systems. Wire-to-wire connectors are versatile and easy to use.

- Wire-to-Board Connectors: When you need to connect a wire to a circuit board, this is the go-to connector. These are typically used in applications where you’re attaching an external component (like a sensor) to a device’s main board.

Material and Design Features

- Durability: The material of the connector matters. High-quality connectors made from materials like brass or gold-plated contacts tend to last longer and offer better performance.

- Contact Type: Connectors can have different types of contacts, such as soldered, crimped, or push-fit. Soldering provides a permanent connection, while crimping allows for a more flexible and reusable solution.

- Insulation: For safety and to prevent short circuits, good insulation is key. Make sure the connector you choose is rated for the environmental conditions your project will face, whether that’s outdoor exposure or high-voltage applications.

Knowing the type of connector you need, along with the features that suit your project, will set you up for a smooth installation process.

3. Environmental and Mechanical Considerations

Your 2 pin connector’s performance won’t only depend on its electrical specifications. It also needs to withstand environmental and mechanical stresses. A connector that works well indoors might fail when exposed to harsh outdoor conditions.

Weather Resistance

If your connector will face exposure to weather, you’ll need a weatherproof solution.

IP Ratings: An IP (Ingress Protection) rating tells you how resistant a connector is to elements like dust and water. For instance, an IP67 connector can be submerged in water for a short time and is fully dust-tight.

Weatherproof Materials: Connectors made from corrosion-resistant metals and durable rubber or plastic can handle exposure to moisture, dirt, or harsh chemicals.

Temperature Range

High-Temperature Environments: If your project will be used in high temperatures, connectors made from materials like Teflon or silicone can withstand heat better than standard plastic.

Low-Temperature Environments: For freezing conditions, opt for connectors that are made to remain flexible and functional even at low temperatures.

Vibration Resistance

Connectors used in automotive, aerospace, or industrial applications often need to resist vibrations. Certain connectors are designed with locking mechanisms to prevent accidental disconnections due to movement.

Choosing connectors designed for specific environmental and mechanical needs will save you time and cost in the long run, ensuring that your system operates smoothly.

4. Connection Methods and Installation

The method you use to install the connector plays a significant role in its performance and longevity. The right installation method can ensure a more reliable connection.

Connection Methods

Soldering: This provides a secure, permanent connection. It’s ideal for high-performance applications where the connection needs to stay intact for a long time without maintenance.

Crimping: Crimping is a popular method for wire-to-wire and wire-to-board connectors. It allows for easy removal and replacement, which is helpful when you need a connection that is reusable or repairable.

Push-Fit: This type is perfect for situations where ease of installation and speed are important. Push-fit connectors don’t require any tools, making them ideal for quick assembly in consumer electronics.

Installation Considerations

Ease of Use: The simpler the installation, the faster you can get your project off the ground. For DIY projects or installations in the field, push-fit connectors or crimped connectors may be more suitable.

Reliability: Choose a connection method that offers long-term reliability. For example, soldering is more permanent, but crimping offers flexibility while still providing a strong connection.

A solid connection method is key to ensuring your connector functions well, and proper installation can make your project easier to manage.

Choosing the ideal 2 pin connector requires careful thought about your project’s electrical, environmental, and mechanical needs. By understanding these factors, selecting the right type of connector, and choosing the best connection method, you’ll set yourself up for success.Remember, while cost and availability are important, don’t compromise on performance. Take the time to evaluate all options and make an informed decision to ensure the long-term reliability and efficiency of your project.