The automotive industry has undergone significant transformations over the past decades, particularly in the realm of electrical systems. From the 1950s to the 1970s, advancements in wiring harnesses, connectors, and insulation materials revolutionized vehicle design, paving the way for modern automotive electronics. This blog explores the key developments during this period and how they shaped today’s automotive electrical systems.

The 1950s: The Birth of Complex Electrical Systems

In the 1950s, as vehicles began incorporating more advanced features such as radio equipment, climate control systems, electric windows, windshield wipers, and enhanced lighting, the automotive electrical system evolved dramatically. Initially, these systems relied on fabric-based wiring harnesses. However, as the complexity of electrical components increased, a new subsystem emerged: the chassis wiring harness.

The Rise of Plastic Multi-Pin Connectors

Aerospace connectors were too large and costly for consumer vehicles. As a result, the automotive industry developed cost-effective plastic multi-pin connectors made from nylon. These early connectors were created using injection molding techniques to form rectangular docking housings with integrated locking mechanisms. The spade terminal housings were secured through contact locking, relying on friction and simple clip structures built into holes within the housings.

To protect connection points in areas exposed to external elements, rubber protective covers were commonly used. While these early connectors had limitations in durability and pin count compared to aerospace counterparts, they met the demands of automotive applications at that time.

The 1960s-1970s: The Integration of Electronics into Vehicles

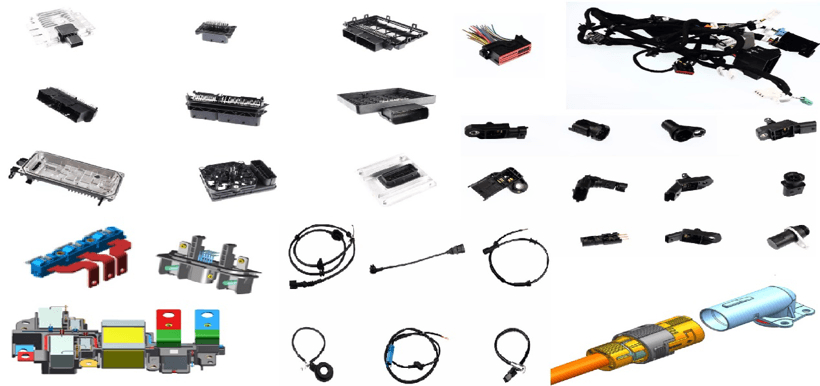

As electronic technologies began to integrate into vehicle electrical systems throughout the 1960s and 1970s, there was a gradual shift towards more sophisticated components. This shift was reflected in various functional parts such as:

- Voltage regulators

- Electronic fuel injection system actuators

- Windshield wiper controllers

- Lighting and wiper control systems

With these advancements came increasingly complex wiring harnesses that incorporated signal processing and sensing functionalities. The layout of these harnesses became denser as manufacturers sought to integrate signal transmission and sensing capabilities into their designs.

Chassis Wiring Harness Design Evolution

By this time, modern chassis wiring harnesses had evolved to use a variety of wire cross-sectional areas, outer sheath materials, and connector types tailored to specific application requirements. This evolution balanced cost-effectiveness with reliability.

New Insulation Materials: A Technological Leap Forward

The mid-20th century saw significant advancements in wire insulation materials. Traditional PVC was replaced by more advanced materials such as:

- Polypropylene (PP)

- Cross-linked polyethylene (XLPE)

- Fluorinated ethylene propylene (FEP)

- Ethylene tetrafluoroethylene (ETFE)

- Thermoplastic elastomers (TPE-U and TPE-E)

- Polyamide (PA)

- Silicone rubber (SIR)

These new materials offered superior electrical performance, high-temperature resistance, abrasion resistance, and hydrocarbon resistance. They also enabled thinner insulation layers. However, due to cost considerations, these advanced materials were used selectively—particularly in high-performance applications like racing or military specifications where TEFZEL wires became popular for their superior properties.

The 1970s: TEF Wire and Racing Applications

In the 1970s, TEF wire gained widespread use in racing due to its exceptional electrical properties, chemical stability, and impact resistance. Its thin yet robust insulation allowed for more compact wiring harness designs that could withstand extreme racing conditions. This period also saw stricter U.S. regulations on fuel efficiency, prompting automakers to enhance engine efficiency while reducing emissions.

The convergence of fuel efficiency demands with European research into fuel injection technology foreshadowed the adoption of electronic engine management systems in the coming decade.

Connector Standardization and Increased Circuit Complexity

As circuits became more complex during this era—incorporating numerous sensors and control mechanisms—multi-pin connector designs were standardized to support up to 100 connection points. Similar to aerospace connectors, these automotive connectors utilized precision-manufactured brass or copper alloy pins formed through stamping and folding processes.

Although most connector casings were rectangular, their designs varied significantly depending on specific applications. Pin-style and slot-style connectors combined contact locking with various insertion locking mechanisms like wedge locking. These mechanisms ensured secure connections while simplifying harness assembly and evenly distributing tension across the connector body.

Materials Used in Connector Bodies

Connector bodies were typically made from materials such as:

- Polyamide (PA)

- Polybutylene terephthalate (PBT)

- Acrylonitrile butadiene styrene (ABS) plastic

- Nylon

These materials were produced using precise injection molding techniques. To enhance weather resistance at mating surfaces between connectors and wire terminals, silicone or fluororubber seals and wire grommets were often employed.

Conclusion: Paving the Way for Modern Automotive Electronics

The period from the 1950s to the 1970s marked a pivotal era in automotive electrical system development. From simple fabric-based wiring harnesses to complex multi-pin connectors capable of supporting advanced electronic systems, these innovations laid the foundation for today’s sophisticated automotive electronics. As we continue to see advancements in vehicle technology—particularly with electric vehicles—the legacy of these early innovations remains integral to modern automotive design.