Automotive connectors are essential components that enable seamless communication between various vehicle systems, ensuring functionality and safety. Below is a rewritten version of the provided content, maintaining the original meaning while reducing repetition and enhancing readability. Automotive connectors are critical for ensuring smooth communication across a vehicle’s electronic systems. Whether it’s a 4-pin or 6-pin connector, these small components play a significant role in keeping your car operational. Let’s explore their roles in different vehicle systems.

Infotainment System

Modern infotainment systems rely on automotive connectors to power features like music, navigation, and hands-free calling. For example, 6-pin connectors are commonly used to link audio components, ensuring stable signal transmission. Specialized tools like pin removal kits are necessary for maintaining these connections without causing damage.

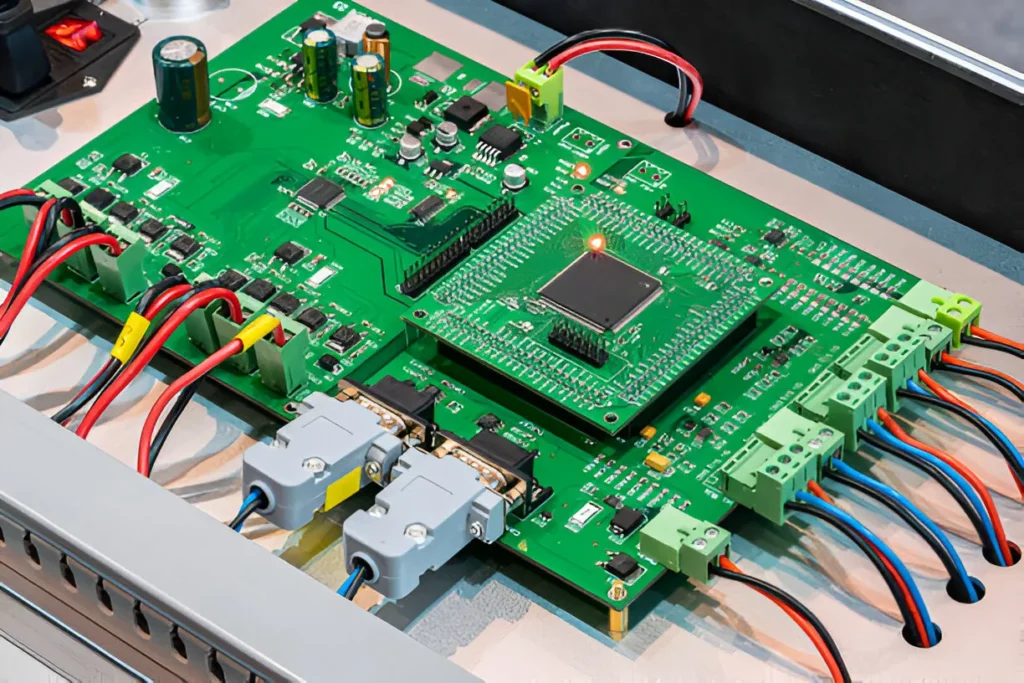

Automotive Connectors Engine Management System

The engine management system acts as the car’s brain, coordinating sensors and control units to optimize performance. Durable 4-pin connectors are often employed for sensors like oxygen or throttle position sensors, designed to endure high temperatures and vibrations. Repair kits can address connector failures quickly, minimizing costly repairs.

Body Electronics System

Everyday conveniences such as power windows and door locks depend on body electronics systems. Multi-pin connectors manage power and signal distribution in these modules. If a pin becomes loose or damaged, tools like connector pin removal kits ensure efficient repairs without compromising other components.

Automotive Connectors Lighting System

Automotive lighting systems, including headlights and taillights, depend on waterproof connectors like 6-pin types to prevent moisture ingress while maintaining reliable performance. Faulty connections can often be resolved using repair kits, restoring functionality effectively.

Battery Management System (BMS)

In electric and hybrid vehicles, battery management system monitor battery health and optimize energy use. High-voltage connections require specialized designs, while low-voltage sections may use standard 4-pin connectors. Loose pins in these sensitive systems can cause significant issues, making proper maintenance tools indispensable.

Installation and Maintenance of Automotive Connectors

Proper installation and upkeep are vital for the longevity of automotive connectors.

Installation Steps:

- Wire Preparation: Strip insulation to match pin specifications (around 4mm) for proper crimping.

- Crimping Pins: Securely attach pins using a crimping tool, ensuring stability by gripping both bare wire and insulation.

- Pin Insertion: Push pins into the connector housing until they lock in place; ensure weatherproof seals are correctly installed.

- Secondary Locks: Engage secondary locks for added security using pliers or screwdrivers.

- Testing: Tug gently on wires to confirm secure seating before testing the system.

Maintenance Tips:

- Regular Inspections: Check for wear, corrosion, or loose pins.

- Cleaning: Use compressed air or alcohol swabs to remove debris.

- Corrosion Protection: Apply dielectric grease sparingly to shield pins from contaminants.

- Component Replacement: Replace damaged parts using repair kits with depinning tools.

- Environmental Shielding: Use weatherproof covers to protect against extreme conditions.

Depinning and Repinning:

For repairs:

- Depinning: Unlock secondary locks and remove damaged wires using terminal release tools.

- Repinning: Crimp replacement wires onto new pins and insert them securely into the housing.

By following these practices, you can extend the lifespan of automotive connectors while ensuring optimal performance across all vehicle systems.